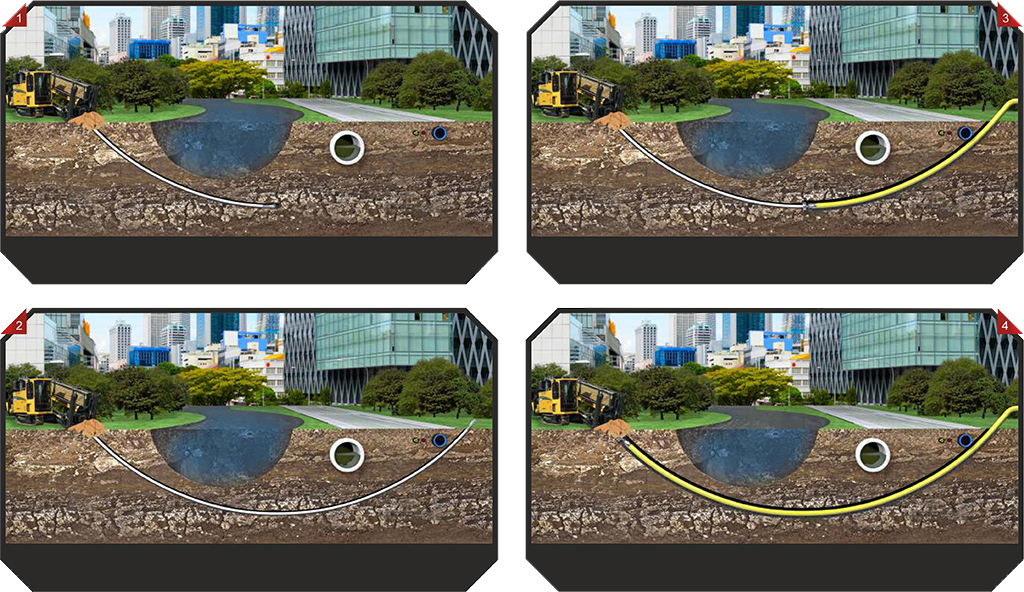

1. The biggest feature that separates the Trenchless Directional Horizontal Drilling System from other horizontal systems is that it can be directed to the pipe laid under the ground. The YYS machine is installed on one side of the route to be crossed, while the other side is laid Steel or HDP pipes to be drawn. A guide hole is drilled with the help of the probe in the determined route from the Directional Horizontal Directional Drilling Machine installed on the surface to the pipe side.

2. This transmitter can be inserted into the directional drilling head and can be used for data such as depth, direction, direction and angle. Drill bits designed for soft or hard surfaces are used in the opening of the guide hole. Thanks to the flexibility of the spindles sent from the machine, the orientation is completed in the direction determined by going down to the desired depth.

3. After the guide hole is opened, the expansion heads start to be enlarged to fit the diameter of the pipe to be laid under the floor. The hole is stabilized by using environmentally friendly chemicals to dispose of the excavated soil and to prevent the hole being opened. After the required magnification is completed, the pipe to be drawn is connected to the rear of the expansion head and pulled towards the machine.

4. In other horizontal drilling methods, the pipe pushing system is used and in the YYS System, the pipe pulling system is used. A special apparatus is inserted between the pipe and the expansion head so that the pipe laid under the floor does not rotate during the pipe drawing process. In order to remove the pipe and close the remaining space, the hole is injected with environmentally friendly chemicals.